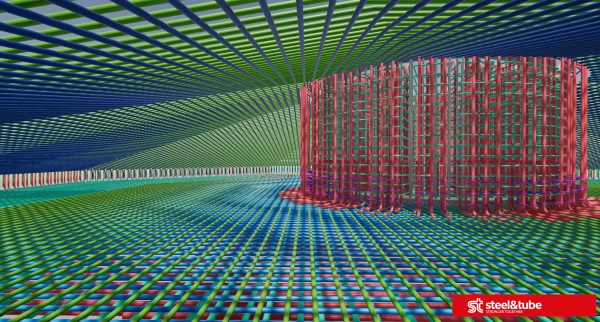

Steel & Tube Holdings – 3D Modelling with QR Code Access.

Steel and Tube Holdings Ltd: 3D modelling with QR code access

Today we profile Steel and Tube Holdings and talk to Christo Erasmus, the South Island Sales Manager, about their use of QR codes on their reinforcing steel to allow scanning onsite which links directly to a BIM model of the steel.

Q1: How long have you been doing this type of work”?

Although 3D modelling of reinforcing is not uncommon internationally, Steel and Tube was an early adopter in New Zealand; in the past 2 years, we have moved to producing 3D Tekla models of the reinforcing steel for our projects, to support the detailing, manufacture, and delivery processes. We also recognised that the models would be useful to others involved in the project and began to share them. More recently, we have gone a step further, displaying QR codes on site that allow other project stakeholders to access the model from any device, simply by scanning the QR code.

Q2: How has this changed the practice of what was previously done?

3D modelling in itself is a significant advantage and a transformational change from the traditional 2D approaches that involved manually marking up drawings and/or using 2D CAD to produce the detailed reinforcing steel documentation.

Previously, a 3D model of the reinforcing steel would be distributed via a link to relevant parties (e.g., steel fixer, main contractor’s site manager); only recipients of the link could access the model. Making models available on-site via a QR code is a shortcut in this process that makes the information available to anybody on-site who wants to access it.

Q3: What were the drivers for this initiative?

The main drivers for implementing QR codes were to increase access and availability and to improve efficiency – the information is easily accessible at the time and the place where people involved in the project need it. At Steel & Tube, we are continually looking for ways to make life easier for our customers needing steel solutions. This is a great example of how we are delivering on this goal.

Q4: What are the main benefits of this process?

The biggest benefit is the ability to easily access the information in the model, on-site and available to any project stakeholder who is interested in using it, at no cost to them. While this may seem a minor achievement, there is an increasing expectation throughout society that technology is used to support all aspects of life, and promoting this trend in construction helps to make the industry attractive and supports the development of a skilled workforce.

Work can be planned and conducted more efficiently. Dimensions and other details can be checked directly from the model. Other parties who would not normally be included in the distribution list for the model can also have direct access to the information; for example, scaffolders can access the reinforcing model to help plan their work by identifying the location of obstacles; anyone planning vehicle or materials access can look at what routes may be possible around the reinforcing.

On a pragmatic level, direct access to more information on-site helps reduce waste in terms of workers’ time and movements. Accessing information needed in the moment is not always easy on-site. It’s a busy environment and it’s difficult to always have the necessary drawings on hand. The use of QR codes to make the model available on any device reduces the need to move on and off-site to access information.

3D modelling of reinforcing steel as a whole improves the design process, assists in clash detection, and helps in optimising the fabrication process. This has implications for waste management and efficient use of resources, as well as health and safety impacts through supporting prefabrication and better construction planning.

Q5: How was this initiative delivered?

The implantation process was twofold. Firstly, we needed to develop 3D modelling that enabled the use of QR codes on-site. We chose to go with Tekla software and employed a design manager with specific Tekla experience to lead the project. Following team training, 3D modelling was trialled on a number of internal projects, interfaces with other software were tested and problems identified were resolved with process changes and support from the software developers.

The second task was to enable QR code access onsite. For this, the only additional actions are to generate a QR code from the model viewing tool (Trimble Connect) and to print and laminate the code to be displayed on-site, both of which require minimal effort and cost. Approval is needed from the main contractor and client on a project to make sure everyone is on board with the open distribution of the reinforcing model via a QR code.

In the space of 2 years, Steel & Tube now use 3D models for about 70% of the reinforcing steel we produce.

Q6: Was there any resistance to this initiative?

As customers and other users have become more comfortable with this new technology and its benefits, it has become more accepted and used on-site. There are some clients who are concerned about the security of the design information, and this has meant QR codes have not been accepted on some sites.

Some steel installers were resistant to move to a purely model-based approach, so we continue to produce 2D drawings from the model, which can also be accessed using the QR code.

Q7: Is there anything you would do differently?

Engaging earlier with project partners to get their perspectives and understand their concerns or needs is important. For example, the installers weren’t able to work only from the model and needed 2D drawings, which can be produced from the model and made available on-site in the same way as the model with a QR code. For 3D modelling overall, the process has gone exceptionally well, and the opportunities are still opening up.

Q8: What are the 5 biggest lessons you learned along the way?

- 1. Steel and Tube have the potential to help drive positive change in the industry. The added value from 3D modelling and information sharing supports a move from being seen as a supplier to becoming a genuine project partner.

- 2. Too much information can be unhelpful. For complicated projects, the information can be simplified by splitting the models by zones, phases, or different buildings on a site with separate QR code/model access for each.

- 3. Play with the opportunities and options that are offered by changes in process – providing the QR code access comes at virtually no cost once 3D modelling is done, but the ways that others could make use of it were not easy to identify.

- 4. Don’t underestimate the time and effort required to bring people along with you in any innovation, it is not a “one and done” process – personal engagement and ongoing connections are important to generate lasting change.

- 5. Health and safety improvements can originate from any action that improves information and planning on-site. Not only is this important for the good of the industry, it is also a valuable consideration in presenting a business case or argument for change.